ASMP also provides comprehensive refurbishing services for machinery:

- refurbishing of mechanical elements, such as regeneration of parts, replacement with new parts, changing bearings, drives, etc.,

- Minor upgrades and regulation of settings during renovation,

- Inventory of replacement parts, cyclical and unplanned inspections.

We provide on-demand maintenance crews, as we have done for years.

Sample refurbishing works

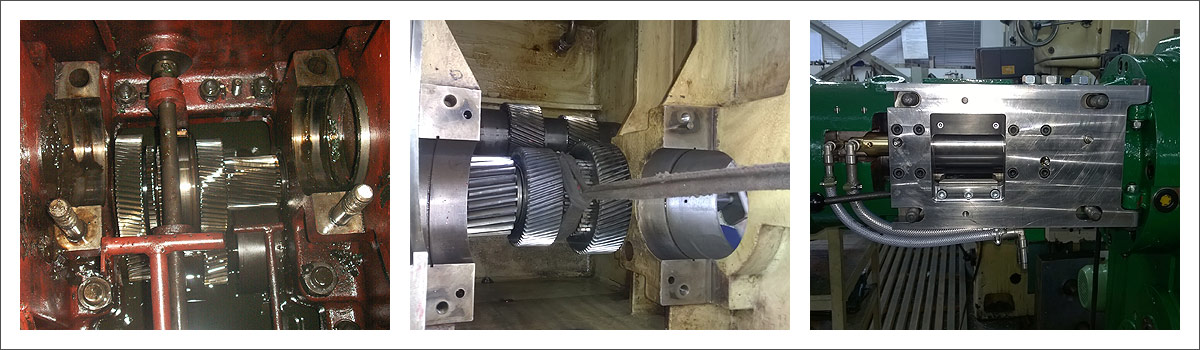

Comprehensive inspection and refurbishing of extruders (originally manufactured in 1976):

- Inspection and refurbishing of the gearbox:

- dismantling and cleaning the gearbox,

- replacing damaged gears,

- replacing bearing components and gaskets,

- installing a new lubrication system (pump, filter),

- constructing a new lubrication system and mounting system for thrust bearing,

- installation,

- painting.

- Inspection and refurbishing of aggregate batch system:

- dismantling and cleaning,

- replacing the filling valve (design and construction),

- replacing doors and the feeder (design and construction),

- constructing new sockets for temperature sensors,

- installation,

- painting.

- Installation of the complete system, and start up at the test site.