The ASMP-AirFix system comprises machines and tools needed to increase the efficiency and speed of the installation process of pocket filters. The filters are linked using special shaped profiles on the AF-Z-600 or AF-Z-1200 line. The linked filters are then fitted to an external frame, and finally mounted in place using another profile. A mounting table, which is an integral part of the system, eases fitting of the frame and completion of subsequent stages of the process. The filters are fitted to the frame using a manual AF-ZR-1 fitting tool.

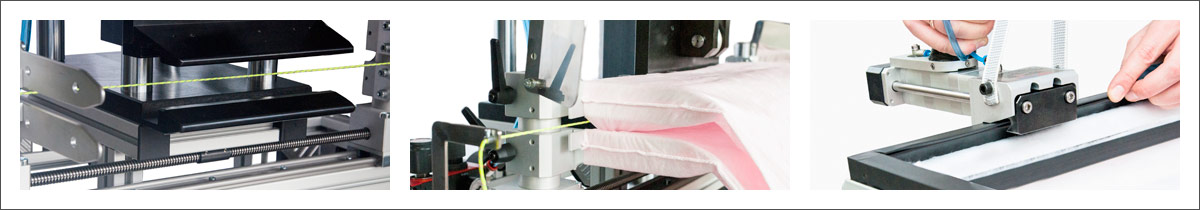

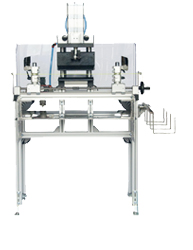

AF-Z-600 and AF-Z-1200 presses

The technology used in the AF-Z presses makes linking filters made of different materials easy. An efficient pneumatic drive (requiring 6 bar pressure) means that as many as 10 filters a minute can be mounted. Ease of use and a time-tested construction guarantee smooth and reliable functioning for years to come.

The technology used in the AF-Z presses makes linking filters made of different materials easy. An efficient pneumatic drive (requiring 6 bar pressure) means that as many as 10 filters a minute can be mounted. Ease of use and a time-tested construction guarantee smooth and reliable functioning for years to come.

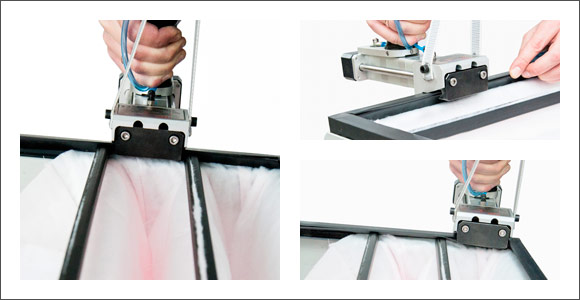

AF-ZR manual mounting tool

The AF-ZR manual fitting tool with pneumatic drive is used to fit the PF-4 (PF4A; PF-4N) profile to the frame in order to secure the filters. Its light weight (1900 grams) and ergonomic shape including a special balancer, make very effective work possible.

AF-SM mounting table

The AF-SM mounting table considerably eases and speeds up the process of mounting the filters in the main frame. The table is designed for frames of from 249 cm to 592 cm, with an easily customised size configuration. An additional asset is the table’s central rotary axis, which makes it possible to carry out the mounting process using the AF-ZR manual mounting tool without the need to move around the table.

The use of the AF-SM mounting table significantly facilitates and speeds the final mounting process.

The AF-SM mounting table considerably eases and speeds up the process of mounting the filters in the main frame. The table is designed for frames of from 249 cm to 592 cm, with an easily customised size configuration. An additional asset is the table’s central rotary axis, which makes it possible to carry out the mounting process using the AF-ZR manual mounting tool without the need to move around the table.

The use of the AF-SM mounting table significantly facilitates and speeds the final mounting process.Additional equipment

We adapt these tools to the customer’s needs individually for every order.

Possible applications of these custom tools:

- custom cutting of profiles PF-4,

- perforation of profiles PF-4,

- drilling of profiles PF-3, PR5, PF-7.

ASMP-AIR FIX air filter mounting system

Downloads