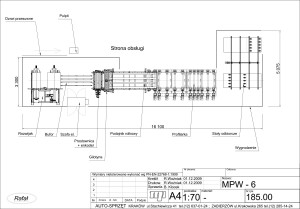

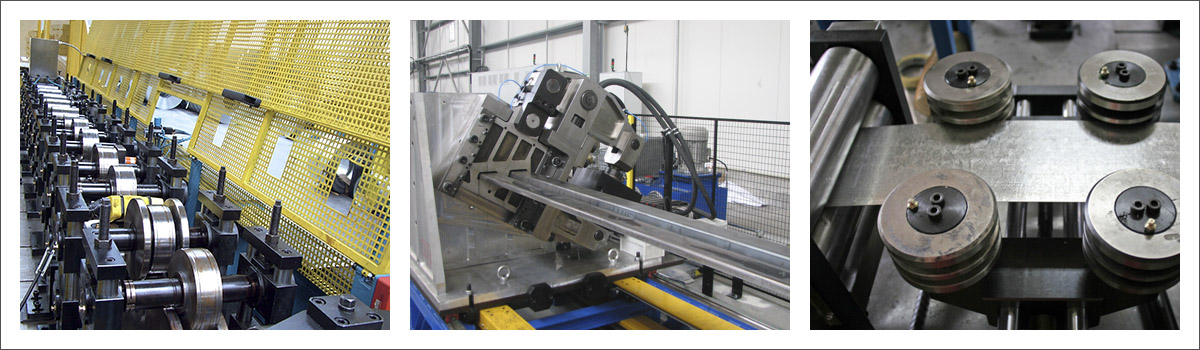

Depending on the level of complexity and final shape of the item to be produced, as well as the material that it is made of, the rollformers are configured with an appropriate number of shaping stations.

Inverter controlled electric motors are used in the drive, which means that there is smooth regulation of shaping speed, which can be adapted to production needs and the individual preferences of the customer.

The shaping process in the ASMP-MPW series is controlled by auxiliary devices: vertical and horizontal grates and side straighteners which can be either single or double.

The ASMP rollforming system uses synchronous cutting, which is possible thanks to the use of high- or low-speed milling discs and a waste- and waste-free cutting press. Six standard versions of the ASMP rollformer are offered:

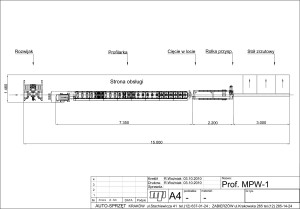

- ASMP-MPW-1

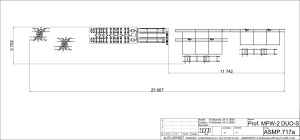

- ASMP-MPW-2 (DUO)

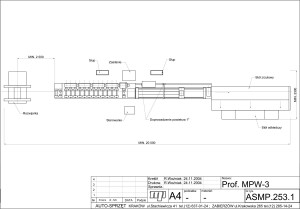

- ASMP-MPW-3 (SINGIEL)

- ASMP-MPW-4

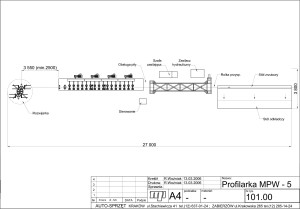

- ASMP-MPW-5

- ASMP-MPW-7

Our professional R&D department, our team of experienced designers, and our qualified staff make it possible for us to design and construct rollformers which meet the expectations of the most demanding customers.